Feature Story: A Visit to the JRE Tobacco Company Operations: Part 1-The Corojo Farm

Source: Cigar Coop

Back in February, I had the opportunity to tour the operations of JRE Tobacco Company. Run by tobacco industry icon Julio R. Eiroa and his son Justo, JRE Tobacco Company is a true vertical integrated crop to shop operation – ranging in everything from growing tobacco, processing tobacco, cigar production, and handling distribution. Today, I take a look at the Corojo farm, the heart of the agricultural operation of the Eiroa family and look at what makes it so unique.

The Eiroa family traces its heritage in the cigar business back to Cuba over a century ago. In 1916, Generoso Eiroa came to Cuba from Spain in 1916 where is became a boat captain for The Cuban Land and Leaf Company. He eventually would acquire farmland and Cuba and become a highly acclaimed grower. Generoso would pass away in 1951. His son Julio R. Eiroa worked in the cigar business in Cuba, but the Cuban Revolution and nationalization of the cigar business would lead to his exile from his home country in 1961. Julio would eventually make his way to the Jamastran Valley of Honduras where he founded the Corojo farm and acquire Camacho Cigars from Simon Camacho. This is the brand the Eiroas family would become synonymous with.

In 2008 the Eiroas would sell the Camacho brand to Davidoff, but that wouldn’t be the family’s exit from the cigar business. After the brand was sold, Julio would continue to own and operate the “Corojo Farm”. Today, the Corojo Farm is a full agriculture and tobacco leaf processing operation. In early 2016, Julio Eiroa would return to the role of brand owner with the launch of JRE Tobacco Company. The launch of JRE Tobacco once again has once again established Julio Eiroa’s operation as a true vertical “crop to shop” operation.

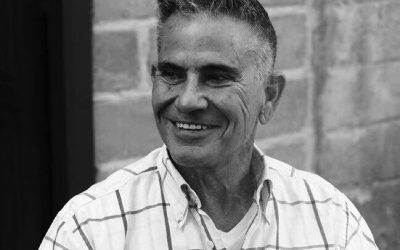

At 79 years young, Julio Eiroa still runs the operations at JRE Tobacco and the Corojo farm. He is up at the crack of dawn each morning and spends time at both the Corojo Farm and the production operations at the factory. He spearheaded and blended the cigars in the Aladino, Rancho Luna, and Tatascan brands of JRE Tobacco. Through his leadership, Eiroa has implemented well-defined processes and innovations at both the Corojo Farm and on the production end at the factory.

Differentiating Authentic Corojo

First up, the farm is named for the Eiroa’s prized tobacco crop – Corojo. The Eiroas grow what is referred to as Authentic Corojo. Corojo tobacco traces its origins to Cuba and eventually made its way outside the island nation. The Corojo plant is one that has been susceptable to fungus and blue mold and as a result, it has often has had lower yields. As a result, the Corojo seed fell out of favor with many growers. Many other growers have worked with hybrid versions of the Corojo plant to mitigate this fungal and mold problem – most notably Corojo 99. In 1997, Julio began to work with the Authentic Corojo seed at his Honduran farm and by the year 2000 he reintroduced the tobacco into the U.S. market with Camacho. While many have continued to work with hybrids, Julio Eiroa has continued to grow Authentic Corojo and today the crops produced on his farms are considered one of the best varietals in the world. It’s something the the whole Eiroa family is very proud of.

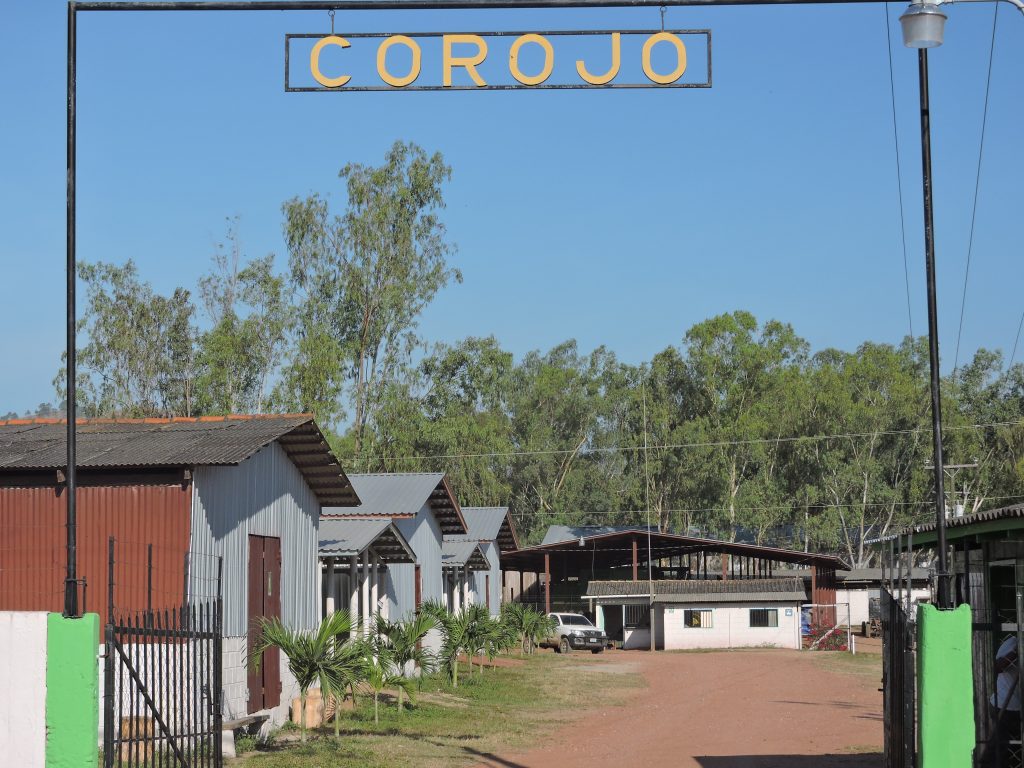

The Farm

The Corojo farm is quite large. There are 650 acres that can be used to grow crops and 52 curing barns. While the farm is not currently at 100% capacity, the farm does have a state of readiness to expand. While the farm is known for its namesake crop, they are also growing other types of tobaccos including habano. At the same time, the Eiroas are also experimenting with other types of tobacco you might not expect to be grown in Honduras.

The land is surrounded by Eucalyptus trees. These trees have a positive allelopathic effect and this contributes to reducing the negative effect other plant growth (mold, fungus, weeds) might have on the tobacco crop.

Bayer CropScience Program

For the past ten years, the Eiroa Family operations for both the farm and the factory have been implementing the Bayer CropScience Program. This consists of a series of Good Agriculture Processes and Good Manufacturing Processes developed by the Bayer Corporation. The Good Agriculture Processes are an integral part of the Corojo Farm’s operations and best practices. The CropScience program promotes concepts such as environmental, consumable crop safety, bio-friendly pesticides, industrial safety, and biosecurity. The Good Manufacturing Processes apply to the production operations at JRE Tobacco.

You see these practices in action the minute you arrive at the Corojo farm. This includes each person entering the farm walking through a disinfectant chamber, spraying down each vehicle entering the farm with disinfectant, and both hand and foot washes. These practices not only promote cleanliness, but one can also infer these help with improving the productivity and yield of the Corojo crop.

The presence of the Bayer CropScience program is quite visible at the Corojo farm. Bright green paint seen on edifices, signs, and other objects – all indicative of the Bayer CropScience Program.

Drip Irrigation

Another innovation the Eiroas are quite proud of is the implementing of a Drip Irrigation System. As the name indicates, this system allows water and fertilizer to slowly drip to the roots of the tobacco plants. Over 400 acres of the Corojo farm has a drip irrigation system in place.

The use of such a system allows the farm to use water and fertilizer more efficiently as well as deliver both more directly to the tobacco plant.

Final Thoughts

The biggest question I had visiting the Corojo farm was I wanted to understand why the Eiroas have been so successful in growing Authentic Corojo where many others have failed. When I saw the combination of the processes and technology implemented by Julio Eiroa and his team over the years, I can firmly understand why

In our next three installments covering this visit, we cover the process from seed to shop and look at how JRE Tobacco uses process and technology to its advantage. We also take a closer look at the life of Julio Eiroa, the man behind the whole operation.

Part 2: A Visit to the JRE Tobacco Company Operations: Part 2-The Agriculture and Curing Operations

Part 3: A Visit to the JRE Tobacco Company Operations: Part 3-The Factory Operations

Part 4: Meeting Mr. Eiroa

Photo Credits: Cigar Coop

Archives

- June 2022

- June 2021

- May 2021

- March 2021

- February 2021

- December 2020

- October 2020

- September 2020

- August 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- January 2019

- October 2018

- August 2018

- July 2018

- April 2018

- February 2018

- January 2018

- December 2017

- November 2017

- October 2017

- September 2017

- July 2017

- May 2017

- April 2017

- March 2017

- November 2016

- March 2016

- February 2016

- January 2016